but work continues

With most of the UK (and the world) in lockdown for the past

5 weeks, you would think that I’d have all three Triumphs up and running and

both Tiger2 and Tabitha Trophy ready for their MOTs.

Sadly, not the case for many reasons, chief of which is that

I’m still working. Yes, it is from home, but as a key worker, I’m still working

my usual 5-day week. Admittedly, I do have some extra time available as I’m

saving around 90 minutes a day by commuting from the kitchen to the dining

room, which is a much shorter journey than I’m used to. So, jobs

have been done in the Man Cave to all three Triumphs.

Tallulah Tiger

Let’s start with Tallulah Tiger, she’s been cleaned, more

than once if I’m honest and I’ve finally got around to the final job that’s

been on my To Do list since I bought her in September 2018, checking the

valves.

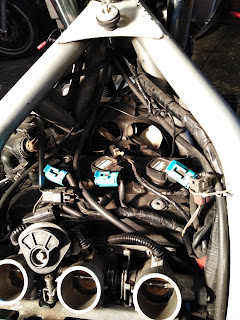

Off came the tank (again) along with the airbox so I could get access to the valve cover. 8 bolts later and a quick tap with a rubber mallet & the valves were accessible. While I have a few spare shims, I acquired from my spare engine (sizes checked with my trusty micrometre), I wasn’t too bothered if I needed to buy more as I wasn’t planning on riding any time soon. It turns out all the valves were in spec. Next job was to clean up all the gasket sealer on the valve cover & clean up the gasket. The gasket was in good condition, so I didn’t have a problem using it again, but the gasket sealer used on the cover took a bit of cleaning. Once done I just needed to put everything back together.

Except nothing is easy. After digging around

in the depths of my toolbox, I found I had no RTV silicone sealer, well I did

but it was so old I binned it. With the throttle bodies and

cylinder head suitably covered with sheets of bubble wrap it was off to the

internet to purchase some more & wait patiently by the door for it to

arrive. 6 days later, Tallulah was back together again knowing the valves were

OK, the airbox spotlessly clean, as was the battery box, and I tucked away at

the side of the man Cave on a trickle charger waiting for Lockdown to end.

On a side note, I had a full set of colour coded luggage

come with Tiger2 which I’ve decided I’ll sell separately at some point, except

for the topbox. Tallulah does have a topbox, but it’s looking a bit worn in

places & is not a Triumph original, whereas the one that came with Tiger2

was. Only thing is it’s blue, not silver, but at least it fits securely on the

Tiger’s rack, unlike the silver topbox that I got with Tallulah. So, I’m going

to respray the Triumph one. I stripped out the hinges, locks and the Triumph

badge and ordered some plastic primer. I’ve already rubbed it down with 1200

grit and it’s had 4 coats of primer. I’m just waiting for some silver paint to

arrive (Peugeot Aluminium Silver) which I’m hoping will be a reasonable

approximation to the original Triumph colour. Not too bothered if it’s a little

out as the existing topbox is way off & it doesn’t look that out of place

when on the bike.

Tabitha Trophy

I know I said I was putting Tabitha aside for a while as I

wanted to get Tiger2 sorted, but I had time to spare while I was waiting for

some silicone sealer for Tallulah, so I decided to tackle the Trophy’s clutch.

When I got her, I noticed that pulling the clutch lever did nothing. I had

already purchased a couple of replacement screws for the master cylinder cap,

so my first job was to drill out the original ones to release the cap. Less than

10 minutes later, the cap was off revealing what looked like very strong Tea

like liquid. Not good. A relatively simple job I thought of bleeding through

some fresh Dot4 and I’d be done.

Jethro Tull rule struck again (Nothing is easy…) when I

couldn’t get any fluid through the system. Not to worry, I have a vacuum bleed

kit somewhere. Another deep dive through the toolbox and the vacuum pump was

all connected to the bleed nipple and primed. Nothing, nada, couldn’t draw any

fluid through the system.

Another trip to the internet and a new seal kit was ordered.

Another 6 day wait (although for clarity, it was the same 6-day wait as for the

silicone sealer) so I could get on. As I also removed the slave cylinder and

the clutch line as well, I cleaned everything up in anticipation of the seal

delivery but found I still had time on my hands. I decided to remove the airbox

to modify it, which as some of you may know means I also had to remove the

carbs. The reason why I wanted to modify the airbox was so that I didn’t have

to remove the carbs in the future each time I wanted to replace the air filter.

Design fault or Triumphs way of making more money every time the air filter

needs replacing by making it a pain in the arse so you leave it for the dealer

to do?

The airbox has captive bolts, so you can’t split it anyway,

meaning the whole airbox/filter unit needs to be replaced. I’m not sure but I

was toying with the idea of splitting the airbox so it can be removed without

taking the carbs off and replacing the stock filter with a K&N version.

Thing is, a K&N filter costs about the same as a new airbox & filter

from Triumph.

Anyway, back to the Clutch. A new seal kit for the master

cylinder arrived & it took all of 10 minutes to replace the seals &

refit the master cylinder to the bike. 2 hours later & I’m still trying to

pump fluid through the system without success. I tried everything, including

vacuum bleeding and reverse bleeding from the slave cylinder using a 500ml

syringe and length of fuel hose. Damned if I could get it to work. I even

stripped the master cylinder & rebuilt it again just in case I’d got it

wrong the first time around.

Yet another trip to the internet to research the issue. I

found many articles about reverse bleeding (tried that), vacuum bleeding (tried

that too) and a couple about priming the master cylinder first (also tried

that). Eventually, I found one article that suggested that the banjo bolt could

be higher than the piston, causing an air lock, especially if the master

cylinder is positioned in its ‘riding position’ It suggested rotating the

master cylinder so that the banjo bolt is as far below the piston as possible

without spilling any fluid out of the reservoir. Tried it and SUCCESS! Within

10 minutes I had a fully working clutch, at least it feels like it’s working. I

put the bike into a high gear & tried rotating the rear wheel with my foot

while holding the clutch in, but it wasn’t an easy thing to do. I suspect that

after standing unused for so long the clutch plates may need some attention,

but I’ll save that for another day.

Success! I have finally managed to unlock the fuel cap. I admit, I wrote to Practical Sportsbike magazine for their help & what came back from them via way of the May 2020 edition was essentially drill the lock out & once open, buy a new tumbler & file the pins so the original key will fit. Well, I didn’t exactly do that as I had one more trick up my sleeve. With the help of a stick, my endoscope and a length of fuel line, I injected some Harpic X10 limescale remover onto the underside of the lock & left it for 20 minutes before rinsing it all out with diesel.

|

| Woohoo! |

I had to do it twice to

clean all the crud off but once done, I inserted the key & felt some

movement. With the aid of a thin flat blade screwdriver for more turning power,

the lock finally gave in & opened. I’ve now removed the whole locking

mechanism & thoroughly cleaned it. It now works fine.

Tiger2

All this time, Tiger2 was staring at me from the bench,

pretty much untouched since I rebuilt the rear brake calliper. I thought it

time I did a little more while I had some time (remember 6 days wait for postal

delivery). The front wheel looked really manky, despite giving the bike a blast

with a pressure washer some time ago. I thought I’d remove the wheel & give

it a good clean. Now this was an easy job, remove the front brake callipers,

check, undo the axle, check, withdraw the wheel from the bike, check. So far

all was going well as I took the wheel outside to give it a thorough clean,

then I heard a metallic clang sort of sound from behind me. I looked back to

see a brake pad hanging below the calliper & a spring sort of thing on the

floor. At first, I thought it was the anti-rattle spring, but it was the wrong

shape. Don’t know where it came from or from what calliper it was supposed to

fit, but a quick look at the workshop manual showed it wasn’t from this calliper.

A thorough search of the floor, which included a sweep revealed a number of

stray washers but no anti-rattle clip. Just in case, I removed the pads from

the other front calliper which confirmed two things, firstly, there is a spring

clip in the calliper, and the one that I heard falling to the floor was

definitely not the correct one. I can only conclude that the previous owner,

lost the original clip & just jammed any old spring clip he had to hand in

the calliper, rather than not use one at all. Another trip to Internet will

shortly be undertaken as Wemoto has them in stock for less than £6 and that’s a

small price to pay for a safety critical part. Oh, the wheel cleaned up OK and

was put back on after cleaning the callipers, the underside of the front

mudguard and the fork lowers.

While I was at it, I found a spare horn on one of the

shelves in the garage, it was the original one from Tallulah which while

working, does sound a little muffled. I decided this was better than no horn at

all so this is now in Tiger2. While I had the front cowl off, I also replaced a

sidelight bulb I noticed had blown and the dash light for the clock.

Once all back together again, I wheeled it outside for yet

another thorough clean, including the underside of the engine which was covered

in oil, followed by a polish of the bodywork. So now there’s a nice clean

Tiger2 sitting back on the bench awaiting a new clutch, which I ordered at the

weekend (2 May).

|

| An altogether cleaner looking T2 |

The good thing about this lock down is that I’m not

commuting, so no fuel costs, no parking charges and I’m not spending money at

lunch times in the local coffee shop. It means there’s a little more money

available to spend on my Triumvirate of Triumphs. Every cloud…

Comments

Post a Comment